Intelligent Infrastructure Design for Utilities (Part 2 of 3)

Dennis F. Beck, PE, President/CEO, SBS

In Part 1 of this series we defined the key elements of intelligent design solutions and introduced how they can support improved workflows within utility organizations. Intelligent design combines advanced asset modeling, support for integrated engineering and standards, and support for configurable enterprise integration. This is in contrast from traditional design tools that can range from manual drawings, sketch-based tools, and two-dimensional CAD or GIS-based design tools.

This article first attempts to identify common issues that utility organizations experience that lead to justifying an intelligent design system. It then gets into some examples of benefits that utility organizations experience by using intelligent design solutions. Many of the details have been provided by members of the SBS Peer Utility Group (PUG), an organization of utilities that meets on an annual basis to share experiences in utility design automation. The PUG has met for over five years now, and we have noticed common patterns emerging in terms of benefits attained. This article attempts to share some of these findings.

Common Issues | How to Know that You Have Problems

Before we can identify the benefits necessary to justify an intelligent design system, it is important to understand the common issues in manual, semi-manual, or non-integrated design solutions. They tend to fall into the categories of general inefficiencies, operational shortcomings, and issues related to information management.

General Inefficiencies:

- Design inefficiency. Designs are often performed with limited information, such as missing field conditions, incomplete or inaccurate base maps, and a lack of detailed engineering properties. Design engineers often do not have the tools or information in place to enable them to perform proper engineering.

- Information and system sharing issues. Designers need to go back and forth from work management to design tools to spreadsheets and materials management systems in order to complete their designs, causing a large loss of efficiency and a need to learn multiple system

- Construction inefficiencies. A lack of good information to facilitate site analysis, inconsistent design standards, materials management issues, field changes, and quality issues due to incomplete or inaccurate designs create inefficiencies in the construction process.

- Manual data entry and re-entry. The most prevalent problem we have noticed has been the need to redraw information multiple times into the target systems, which not only takes time, but slows down the flow of information necessary to operate systems. This also impacts safety and the ability to readily gather critical information on a timely basis, a requirement that is increasingly necessary for regulatory requirements as well as advanced utility applications such as ADMS.

Operational Shortcomings:

- Poor information sharing. This operational shortcoming can range from slowdowns in approval processes to safety issues caused by not making critical information available to project and operations stakeholders.

- Materials management issues. These issues occur due to lack of accurate bills of materials and a lack of standards, which causes a wide range of issues with materials warehousing and supply chain management.

- Lack of compliance. Risks related to lack of compliance are caused by a lack of design standard enforcement, a lack of design details, and an overall inconsistency across the organization.

Information Management:

- Safety issues and close calls due to uncoordinated work, records out of date, and broken as-built workflows.

- Customer service issues due to lack of available information or responsiveness.

- Generally poor information quality, including out of date network representations that are needed to support advanced technologies.

- Inability to support new applications due to out-of-date information.

- Lack of data to enable future asset management initiatives.

- Outdated systems that are not upgradeable due to custom developments that are costly to upgrade. The upgrades can sometimes cost more than the original installation.

- Poor system performance, typically caused by custom, out-of-date systems.

Discovering the Benefits

Our understanding of benefits from this next generation of design tools continues to advance as more and more utility organizations adopt the intelligent design paradigm. While there are benefits across the entire asset lifecycle, this article will focus on three main areas:

- Design and workflow efficiencies

- Construction improvements

- Better information for advanced applications

Design and Workflow Efficiencies

In model-The most quantifiable benefits for intelligent design solutions are centered around improvements in design and workflow efficiency improvements. These are inherently driven by the foundations of intelligent design—model-based design, advanced integration, and application improvements. Here are some of the key benefits:

- Improved information access. Integrated solutions such as Enterprise Asset Management (EAM) and GIS provide the necessary information to access key applications within engineering design and construction workflows. EAM makes work orders and compatible units available without having to leave the design tool. GIS can be accessed via service-based integration to provide necessary background data, current asset representations, and various forms of analysis to support design.

- Engineering automation. Model-based representations of utility assets enable the automation of common engineering design functions, including 3D asset representations necessary for performing line sag analysis, structural analysis, and underground modeling of conduit to support pulling tension and clearance analyses.

- Reduced manual data entry and redrawing. Data redrawing has been a common problem at utilities for decades stemming from the need to have a richer, more accurate set of information to support design. This is often in contrast to the GIS user, who often can benefit from less-detailed information to support safe and timely operations activities. Intelligent, model-based representations of utility assets allow organizations to present and share this information with different user personas without having to go through redrawing operations, which provides more timely information to support new applications.

It is not uncommon for organizations that implement intelligent design to achieve a twenty percent or greater improvement in design productivity. Some organizations have achieved significantly more. One SBS client has reported a savings of approximately 6000 hours per year just by reducing data entry for materials lists. For an example of a distribution utility organization’s experience, please read “Integrated Design Is More Efficient” on the SBS blog. For an example of substation protection and control design efficiency improvements, please refer to “The Value of Intelligent Substation Design – A Perspective of Three Utilities.”

For most organizations, the payback period for design efficiency improvements tend to justify the expenditure for an intelligent design system. Our SBS intelligent design solution customers have experienced a payback period ranging from eight to twenty-four months. It is important to look beyond the efficiency improvements, however, as there is significant, more strategic value that intelligent design offers to utility organizations.

Construction Improvements

One of the important realizations of intelligent design is that designs are not only more efficient, but they offer higher quality, which can translate into significant benefits when the design moves into the construction process. This is driven, once again, by having rich models with 3D representations working in conjunction with the information necessary to drive better decisions. Here are a few examples:

- Design quality. 3D designs offer inherently better quality. Having the accurate 3D representation allows organizations to perform better analysis for things such as clearance checking and constructability. This in turn makes construction safer and more efficient while reducing costly field changes that impact not only the project cost, but also the project schedule. Schedule impacts can often be more costly to the utility shareholders than cost overruns.

- Better materials management. Intelligent design supports better materials management in several ways. The properly defined asset models can be used to drive the designs to a high-level of standardization, which reduces the extensive amount of one-off compatible units that some utility organizations will stock within their inventories. These kinds of improvements can offer tremendous savings throughout the supply chain of a utility. Better materials management also serves to ensure that construction is more standardized, improving build efficiency. Auto-generation of an accurate, sufficiently detailed bill of materials ensures that the right materials are used on the construction project without having to improvise in the field.

- Detailed models. Having a sufficiently detailed model that can be viewed in 3D also ensures that the review cycle can be performed by a broad audience of stakeholders who need to approve projects. These stakeholders often do not have the engineering skills to sort through stacks of dozens or perhaps hundreds of 2D design documents to discern what is being built. Visualization of a 3D model within a web-based viewing tool opens up the review cycle to timely reviews and approvals from all stakeholders, reducing the risk of having to make costly field changes once construction has started.

- Information sharing. The ability to share this information during the construction process enables the use of BIM-based applications to support requests for information (RFIs) from the field, which speeds up the field change process, once again reducing the cycle for field changes. Other BIM capabilities include visual project management of construction progress and improved construction analytics.

Intelligent design solution users are in the earlier stages of generating construction benefits as they move to more and more digital construction workflows. For further examples of the significant benefits utility organizations have achieved during the construction phase, please refer to the blogpost “The Value of Intelligent Substation Design – A Perspective of Three Utilities.” Of particular note is the improvement in reducing field change orders due to higher design quality.

Better Information for Advanced Applications

While the sections above list benefits that can be readily quantified to justify an investment in intelligent design solutions, this section offers some strategic reasons for moving forward with intelligent design. The primary strategic benefits involve the ability to gather and share information related to asset lifecycles starting with the initial design. This information then supports a wide variety of advanced applications that are starting to enter the workplace.

Many utilities are striving to establish a digital twin strategy for their organizations. Intelligent design solutions address a critical element of digital twin strategy by authoring the digital twin during the normal business workflow at the inception of the design process. Once the digital twin is created, it persists throughout the construction process, gets modified during as-built verification, and then supports downstream applications that rely on detailed, accurate asset models.

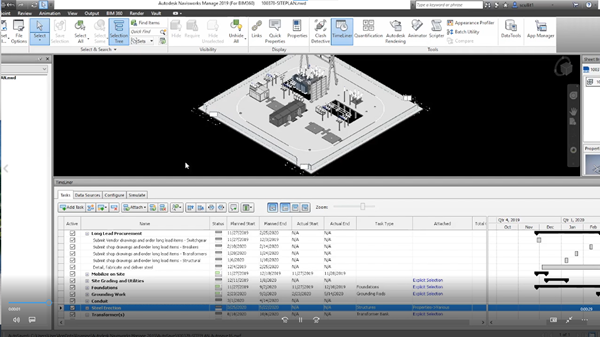

The example below shows a visualization of the construction process by viewing the 3D model in conjunction with Primavera project management software. The visualization is being hosted by Autodesk Navisworks.

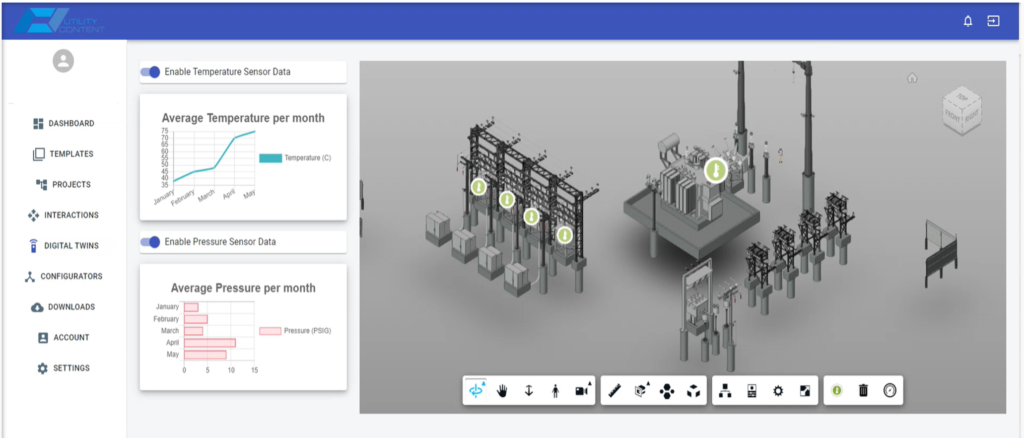

The digital twin models created during design can also be extended to view the status of the extensive amount of Internet of Things (IoT) sensors that are now populating the electrical smart grid. The example below is a prototype developed by SBS with a leading U.S. utility to create a way of easily visualizing asset performance. This was accomplished by synthesizing the tremendous amount of substation sensor data that is created every day into an actionable user interface. The 3D, intelligent design model can be readily imported into web-based visualization platforms—in this case, Autodesk Forge.