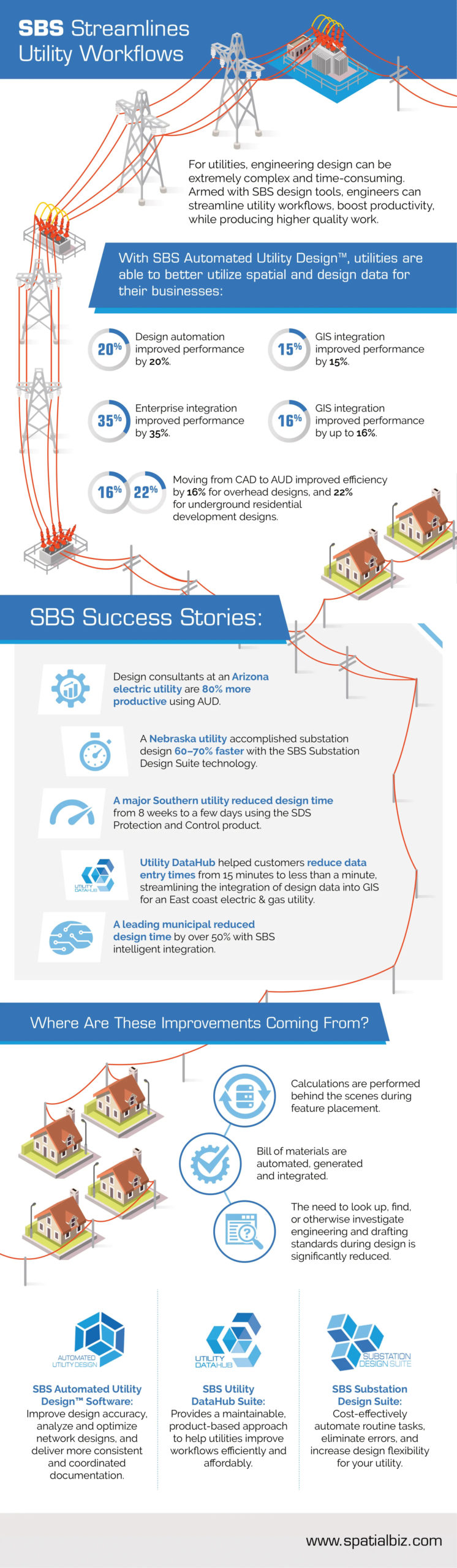

Leading Engineering Firm Uses SBS Automated Utility Design (AUD) for Wind Farm Projects

Introduction

Last summer we had the opportunity to hear from a number of our Automated Utility Design (AUD) customers at the annual SBS Peer Utility Group, held at Puget Sound Energy in Bellevue, Washington, USA. One of our partners, Atwell, LLC gave a particularly interesting presentation on an innovative use of AUD for the design of wind farms.

Atwell is a full-service consulting, engineering, and construction services firm and their experience in engineering design combined with their long history in power and energy systems formed a great combination to provide a creative solution making renewable energy an affordable reality.

AUD has an excellent track record for performing integrated distribution design for electric and gas utilities. The product, based on AutoCAD Map3D, can natively perform design layout, voltage drop analysis and a nearly unlimited set of custom design checks when rules are configured within the system. Now we have learned that it can also be a great tool for designing the collection systems that support the design of wind farm systems.

Making Renewable Energy Design Projects Achievable

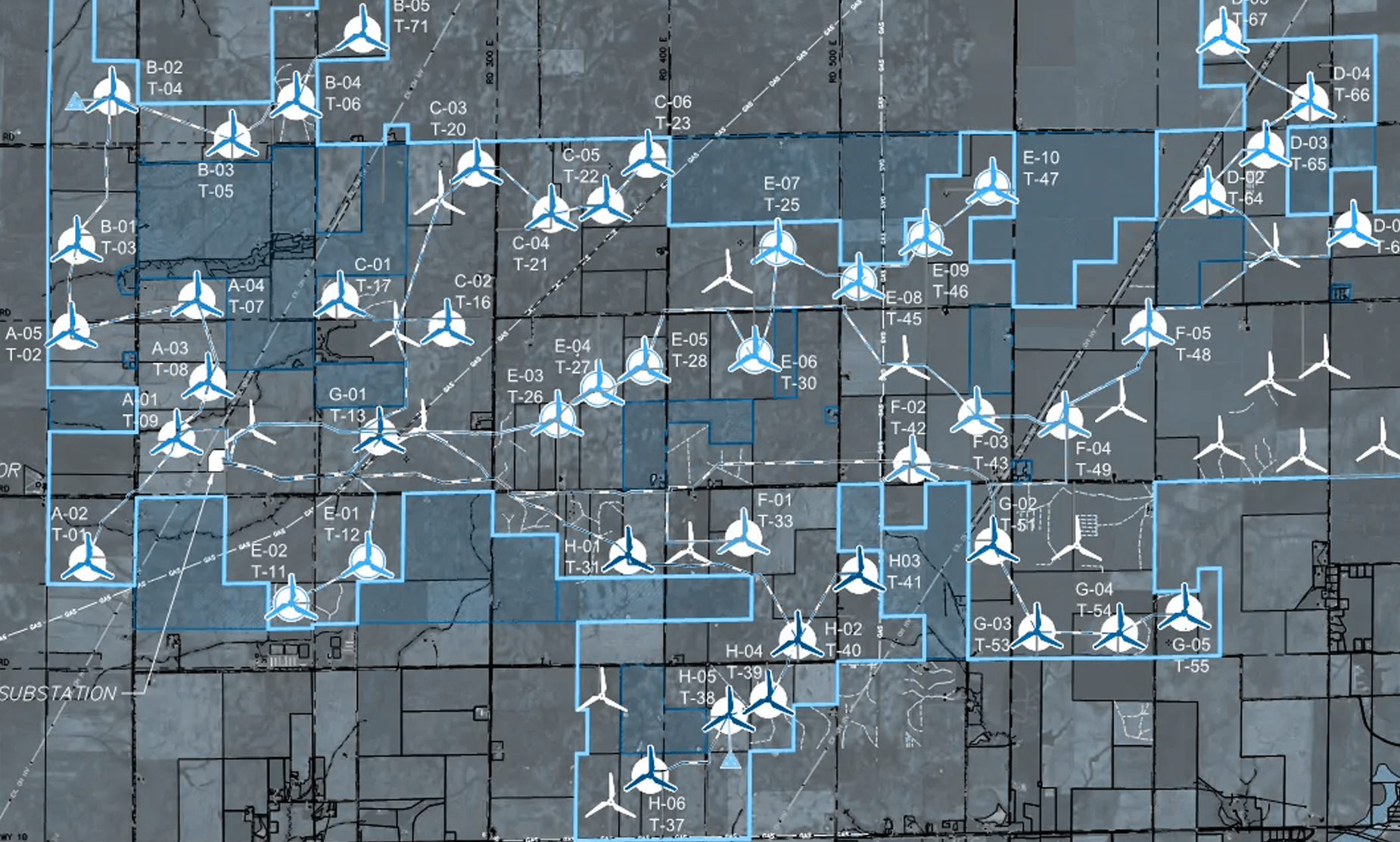

The design of wind farm collection systems can be a challenging task. Traditional electric distribution system designs performed by AUD typically span a few city blocks; a wind farm can stretch 50 to 100 square miles, or more. The collection system, which consists of medium voltage cables between the wind turbines, in the Atwell design project exceeded 80 linear miles. These large-scale geographies are further complicated by numerous design constraints such as non-participating properties, environmentally sensitive areas such as wetlands and cultural sites and transportation corridors such as underground gas pipelines, railroads and roadways. It is not uncommon to have hundreds of crossings that need to be managed as part of the design and construction process.

These competing constraints make the design process complex and if the design is not properly optimized project costs can spiral out of control causing the well-intentioned goal of achieving renewable energy standards to be cost-prohibitive.

How Automated Utility Design™ Streamlines Wind Farm Design

To understand how AUD can streamline wind farm design it is important to understand the current, semi-manual process. A wind farm project typically involves initial studies which then support creation of preliminary collection system layouts. The layouts are analyzed to determine groupings of turbines for purposes of defining conductor pathways as part of the collector system. All of these steps are subject to numerous constraints mentioned above. Many of these constraints can have very significant impacts on overall system costs. And they can get complex quite quickly – a moderately sized project can easily have hundreds of constraints that can impact an optimal design.

The Atwell team had been using a combination of AutoCAD, multiple spreadsheets and digital maps to perform the layouts and associated analyses. By using AUD they were able to include cable sizing, cable

loading along with the wide variety of constraints involved in the projects. These were then processed dynamically to generate summaries of the conductor designs. High-cost constraints such as borings can be included in the costing summaries. The results allowed Atwell to create a highly optimized design with greatly reduced manual effort.

Other benefits included auto-generation of callouts, sequential naming of splices over long conductor runs and optimal splice locations which all help to improve constructability in the field.

Atwell’s Experience in Generating Real Benefits

Using Automated Utility Design provides the opportunity for numerous, real benefits when designing wind farms. Here is what the team at Atwell, LLC has experienced:

· AUD greatly reduces interdependencies and manual data entry

· AUD provides design change flexibility

· Routine tasks become highly automated – a typical manual iteration can take 1 ½ days to implement but can now be accomplished in just minutes.

· Material usage can be much more highly optimized

· Overall design time is significantly reduced, while improving overall quality

· Better designs support better construction, reducing field construction costs and project changes.

Conclusion

Automated Utility Design has a highly configurable set of modeling constructs along with a powerful rules engine that can streamline many aspects of utility construction. We look forward to hearing about the design challenges you are having and will welcome the opportunity to discuss how AUD might work for you. Please contact SBS at [email protected], or feel free to meet us at our next Peer Utility Group event. Visit the PUG site at http://spatialbiz.comm/support/peer-utility-group/.