Blog

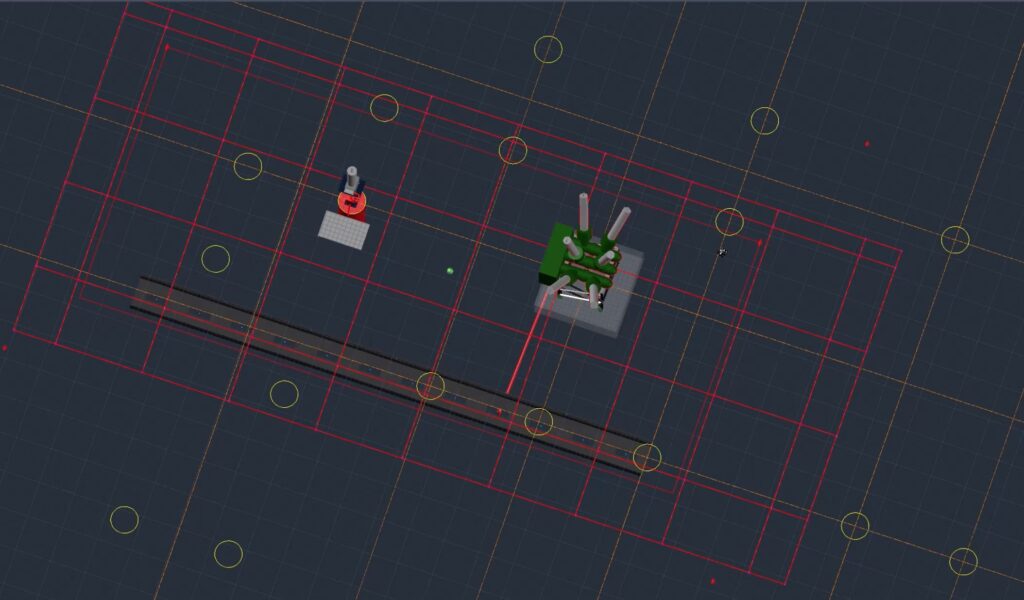

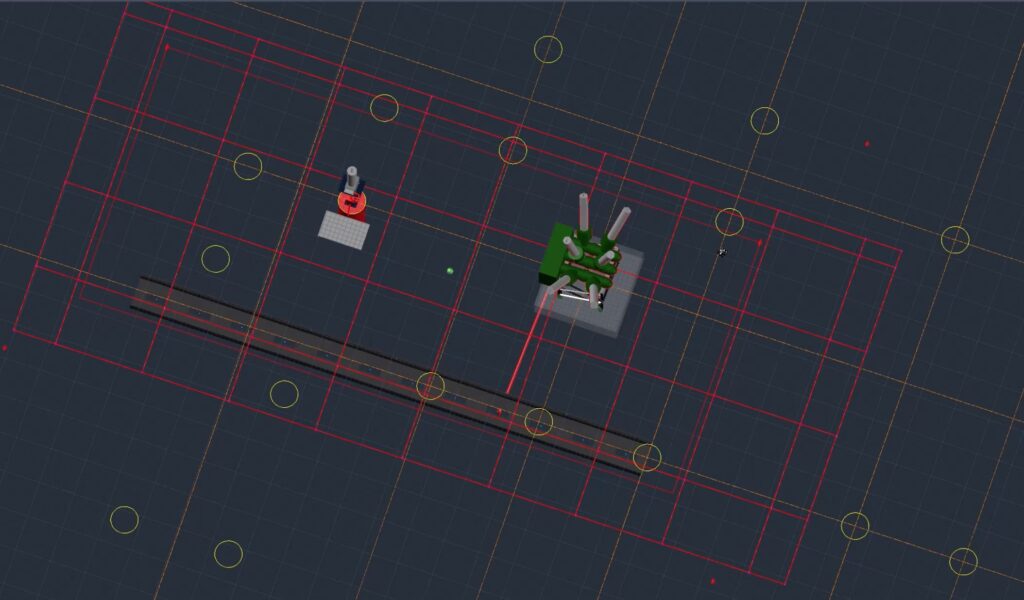

Below-Grade Automation in SDS-Physical

Faster, More Accurate Substation Design Designing below-grade systems is one of the most detail-heavy and risk-sensitive aspects of substation engineering. Cable trenches, conduits, control circuits, […]

Read More >

Below-Grade Automation in SDS-Physical

Faster, More Accurate Substation Design Designing below-grade systems is one of the most detail-heavy and risk-sensitive aspects of substation engineering. Cable trenches, conduits, control circuits, […]

SBS 9.2 Software Release: Everyday Improvements

Smoother sign-in experience and quality of life improvements make energy and broadband design easier and faster. SBS version 9.2 is now available for Automated Utility […]